X-Ray & Gamma Radiography

Technique capability:

- All type of materials can be inspected

- Produces the permanent evidence (radiography film)

- Length of the defect can be sized

Ultrasonic Testing

- All type of materials can be inspected.

- Inspection item can be examined from one side access itself.

- Length & Depth of the defect can be sized.

Magnetic Particle Testing

- Only ferromagnetic materials can be inspected.

- Detects Surface & Near Surface defects

Liquid Penetrant Testing

- All types of Non Porous materials can be inspected.

- Detects open surface defects.

Corrosion Mapping (UT C-Scan & B-scan)

- Ferrous & non ferrous materials can be inspected

- Accuracy of measurement is ± 0.2mm

- Scan speed of 100 mm X 50 mm per second

Remote UT Inspection (Crawler System)

- Only ferrous Structures can be inspected

- Produces B-Scan images of thickness, which can be saved and kept for future audit.

- Working height range 30m

Phased Array Ultrasonic Testing (P.A.U.T)

- Ferrous & non ferrous materials can be inspected.

- Inspection in limited access area, where there is limited access for raster scanning.

- Inspection speed – In a linear scanning whole weld area

will be inspected, which tremendously reduces the

inspection time. - High probability of defect detection.

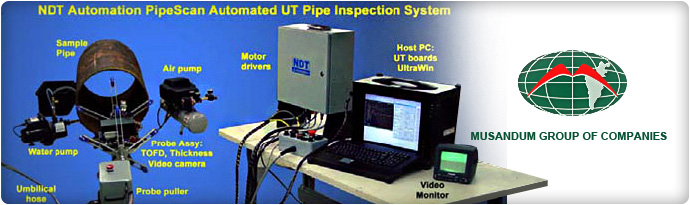

Time of flight Diffraction Ultrasonic Testing (T.O.F.D)

- Ferrous & non ferrous materials can be inspected.

- Precise defect sizing.

- High probability of defect detection.

- High speed weld inspection.

- High speed cladding surface corrosion screening.

Alternative Current Field Measurement (A.C.F.M)

- Length & depth of the defect can be measured accurately

paint and other protective coatings several millimeters

can be left on - The primary advantage is that little or no surface

preparation is need for a test. - All data can be stored for audit

Surface Eddy Current Testing (E.C.T)

- Ferrous & non ferrous materials can be inspected.

- Capable of inspecting through surface coatings, such as

paintings up to 2 mm. - Rapid Surface inspection.

Eddy Current Tube Testing (E.C.T)

- Only non ferrous tubes can be inspected.

- Detects discontinuities such as corrosion, erosion, wear,

pitting, baffles cuts and cracks. - Inspection speed 2m/s.

- Productivity 800 tubes per shift (based on site condition

may differ)

Remote Field Eddy Current Testing (R.F.E.C.T)

- Only ferrous tubes can be inspected.

- Detects discontinuities such as corrosion, erosion, wear,

pitting and baffles cuts. - Inspection speed 0.3m/s.

- Productivity 400 tubes per shift (based on site condition

may differ).

Internal Rotary Inspection System (I.R.I.S)

- Both ferrous & non ferrous materials can be inspected.

- Detects general wall thinning such as corrosion &

erosion and localized defects such as pitting, wear scars. - Measures the absolute wall thickness of the tube.

- Inspection speed 2inch/s.

- Productivity 80 tubes per shift (based on site condition

may differ)

Remote Visual Inspection (R.V.I )

- Our RVI tool is designed in a way that can be rotated

at 90°. - Minimum accessible opening for RVI tool is 10mm.

Positive Material Identification (P.M.I)

- Identifies the material chemical composition in few

seconds. - Capable of inspecting fixed structures.

- Inspection can be performed in a limited access area.